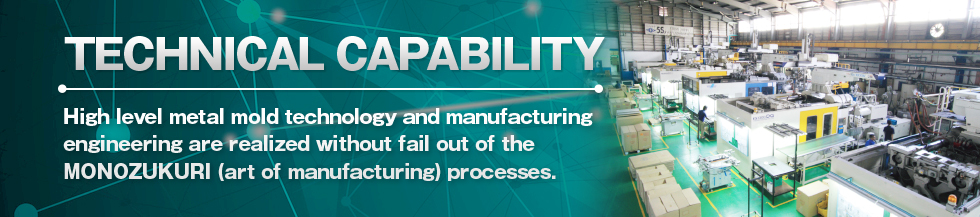

Manufacturing processes of Ryoka Malaysia.

We offer high level technical capability realized by fusing traditional technologies developed over 50 years at Ryoka Kogyo in Japan, a plant specializing in plastic molding and assembly, and new technologies.

1Design/metal mold

Experienced engineering staffs realize customers’ requirements.

Engineering staffs with abundant experience and accomplishments are involved from the early stage of quality product manufacturing exploiting the most advanced technologies such as flow analysis by CAE and 3D/CD design.

Technical consultation

Technical consultation

2Molding

We accommodate large sized products to small sized products.

We have a wide range of molding machines covering 30t to 1600t, gas assisted facilities and heat and cool facilities. Simplified clean room environment for molding applicable to white goods is useful to meet the requirement of the customers.

Metal mold maintenance

Metal mold maintenance

Molding plant

Molding plant

Simplified clean room molding room

Simplified clean room molding room

3Design and development of jigs and tools.

Highly efficient production by development of jigs and tools by ourselves.

We also design, develop and sell jigs and tools made by placing importance to stable quality and productivity.

4Secondary processing (painting, printing)

We make customers’ products more valuable.

We make high value-added products through advanced manufacturing engineering including electrocasting masking painting and highly functional painting such as high gloss painting performed in a high level clean room for painting.

Painting robot

Painting robot

Printing machine

Printing machine

5Assembly

Integrated assembly production line

Products assembled by welding, compression bonding, adhesive bonding and screwing are produced with high reliability from our flexible production line, and highly appreciated by customers in various fields.

Assembly line

Assembly line

Clean room

Clean room

6Quality assurance

Quality assurance system to be highly trusted.

Each production process is strictly controlled to satisfy the quality standards of our customers. Furthermore, we have established a quality assurance system by employing measurement using high precision measuring instrument, environment test and durability test.

- Coordinate measurement

- Profile projector

- Heat chamber

- Eraser tester

Quality assurance office

Quality assurance office